Leave Your Message

In various industries, the use of HPMC thickener has gained significant attention. Dr. Lisa Chen, an expert in polymer science, states, "HPMC thickener transforms formulations, enhancing efficiency and performance." This insight highlights the impactful role of HPMC thickener across sectors like construction, food, and pharmaceuticals.

The versatility of HPMC thickener cannot be overstated. Its ability to improve texture and stability makes it a vital additive. For instance, in the food industry, it ensures a smooth consistency in sauces and dressings. Additionally, its water-retaining properties are crucial in construction materials, offering better workability and adhesion.

Despite its many advantages, there are challenges to consider. Some formulations may not react well with HPMC thickener. This can lead to unexpected textures. It’s essential for manufacturers to test extensively. The benefits of HPMC thickener are undeniable, yet the application process requires careful attention to detail.

HPMC thickener plays a crucial role in the construction industry. It enhances the performance of cement-based materials. This thickener improves workability and consistency in mortar and plaster. It allows for better adhesion to surfaces. Workers appreciate how it helps maintain the right viscosity during application.

Using HPMC can reduce the risk of cracks and improve durability. It also provides a strong resistance to water. This feature is beneficial in various weather conditions. However, its effectiveness depends on the correct dosage. Too much thickener can lead to a sticky mixture. Conversely, too little may not achieve the desired viscosity.

The benefits of HPMC are clear. It streamlines construction processes. Yet, builders must understand how to use it properly. Experimentation may be necessary to find the optimal balance. Some projects might require adjustments based on local materials and conditions. Striving for improvement is part of the process.

The chart below illustrates the top 10 benefits of HPMC thickener across various industries, highlighting its performance enhancement capabilities, particularly in the construction sector.

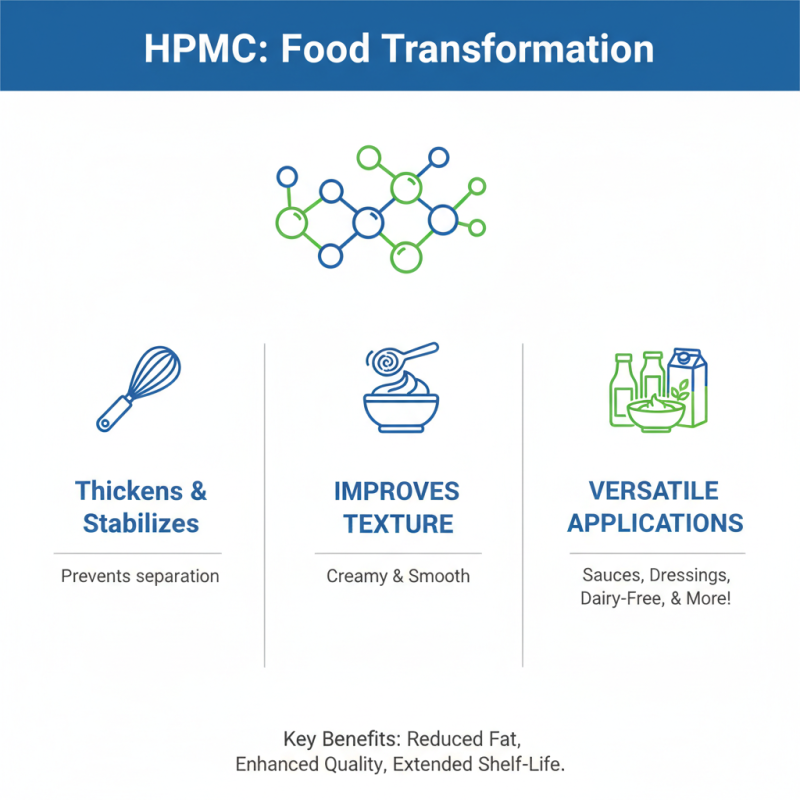

Hydroxypropyl methylcellulose (HPMC) is transforming food products. This thickener enhances stability and improves texture, making it a popular choice in various food applications. Many products, like sauces and dressings, benefit from its unique properties. With HPMC, creamy textures become easy to achieve without additional fats.

One significant benefit is its ability to retain moisture. This is crucial for baked goods. A well-moistened cake or muffin remains appealing and fresh longer. However, using HPMC isn’t always straightforward. Overuse might lead to an undesirable gummy texture. Therefore, finding the right balance is essential for optimal results.

HPMC can also support emulsions, which are delicate mixtures. For instance, salad dressings remain uniform and visually appealing with HPMC. Its influence on viscosity helps prevent separation. The challenge lies in achieving the right consistency. Too thick can be unappetizing; too thin may not meet consumer expectations. Crafting the perfect formula requires careful experimentation and consideration of consumer feedback.

HPMC thickener plays a crucial role in pharmaceutical formulations. It enhances the viscosity and stability of various products. By creating a gel-like consistency, it helps in suspending active ingredients effectively. This is essential for ensuring accurate dosing and uniform distribution. The thickening properties of HPMC improve product texture, making it easier for patients to consume.

In formulations like gels and creams, HPMC thickener increases adherence to skin and mucosal surfaces. This provides prolonged action for topical treatments. However, not all formulations benefit equally from using HPMC. Some may require adjustments in concentration to achieve optimal performance. A careful balance must be struck; otherwise, the product flow could become too thick.

Moreover, the interaction between HPMC and other ingredients can lead to unexpected outcomes. Variations in temperature and pH levels might affect its functionality. Manufacturers need to test and refine their formulations regularly. This ongoing process ensures that the final product meets desired specifications without compromising on quality. Attention to detail is vital in these processes, as small mistakes can lead to larger issues.

HPMC thickener plays a crucial role in personal care products. This natural polymer enhances product texture and stability. It creates a smooth, luxurious feel on the skin. Its ability to retain moisture makes formulations effective and appealing. Users appreciate the soft and velvety application, enhancing their overall experience.

In body lotions and creams, HPMC thickener improves viscosity. This leads to a more uniform product distribution during application. An ideal consistency encourages consumers to use it regularly. However, achieving the perfect thickness can be challenging. Some formulations may become too thick or too runny. A delicate balance is necessary for optimal results.

In shampoos and conditioners, HPMC thickener aids in even distribution. It helps to coat each strand, leaving hair soft and manageable. Yet, excessive use can weigh down hair. Striking the right proportion is essential. The focus should remain on enhancing the user experience while ensuring product efficacy. Adjustments may be needed based on formulation goals and consumer feedback.

HPMC thickener is essential in paints and coatings. It significantly improves viscosity control, ensuring a stable formulation. By adjusting the consistency, it enhances application and performance. This thickener allows for a smoother finish, making surfaces attractive.

However, achieving the perfect viscosity can be tricky. Too much thickener may lead to clumping. Conversely, too little can result in poor coverage. The balance is vital for effective results. Manufacturers need to monitor viscosity closely. Adjustments may be necessary throughout production.

Workers appreciate HPMC's ease of use. It dissolves well in water, simplifying the mixing process. However, the correct temperature and mixing speed must be observed. Minor deviations can affect the final product. Continuous testing ensures that the desired properties are achieved consistently.