Leave Your Message

In the realm of formulation science, selecting the appropriate emulsifiers is crucial for achieving the desired stability and texture in products. Among the various emulsifying agents available, Polysorbate Emulsifiers stand out due to their versatile properties and effectiveness in creating stable emulsions. These surfactants are widely used in multiple industries, including cosmetics, pharmaceuticals, and food products, owing to their ability to lower the surface tension between immiscible liquids, allowing for a uniform blend.

As formulation experts and manufacturers gear up for 2025, understanding how to choose the right Polysorbate Emulsifiers will be integral to optimizing product performance and consumer satisfaction. With an increasing focus on clean labels and natural ingredients, the selection process must also consider compatibility with other formulation components, regulatory requirements, and the end user’s experience. This guide will elucidate the factors to consider when selecting Polysorbate Emulsifiers, enabling formulators to create high-quality, stable products tailored to modern consumer needs.

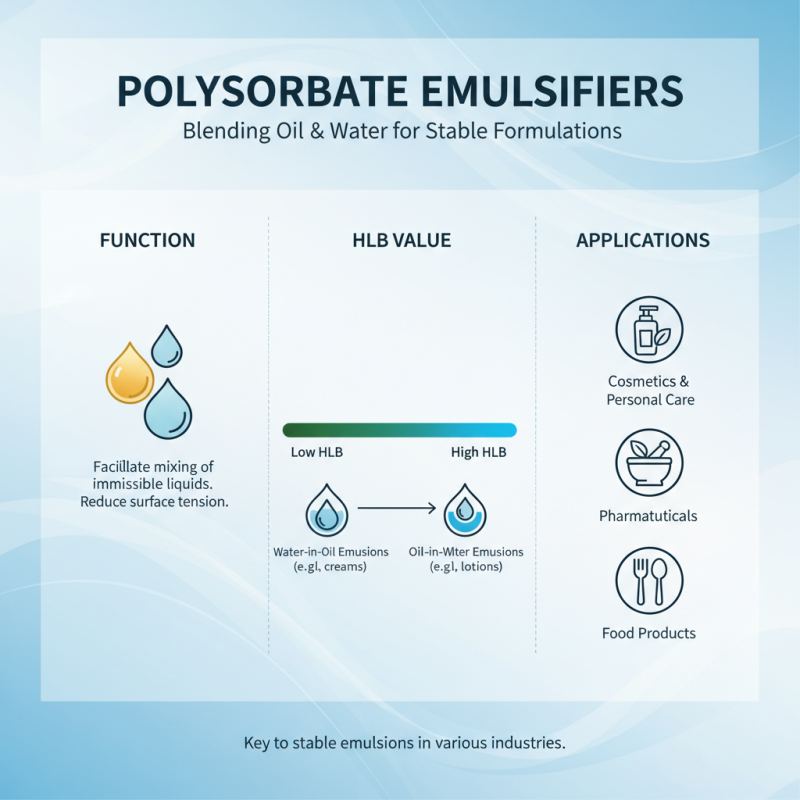

Polysorbate emulsifiers play a crucial role in many formulations, particularly in cosmetics, pharmaceuticals, and food products. These surfactants facilitate the blending of oil and water, which are naturally immiscible, by reducing the surface tension between the two phases. Understanding the functionality of polysorbate emulsifiers requires an insight into their hydrophilic and lipophilic balance, as this property determines their efficiency in stabilizing emulsions. For instance, higher hydrophilic-lipophilic balance (HLB) values indicate a stronger affinity for water, making them ideal for oil-in-water emulsions, whereas lower HLB values favor water-in-oil emulsions.

When selecting the right polysorbate emulsifier for a specific formulation, it is essential to consider various factors, such as the desired stability of the emulsion, the nature of the active ingredients, and the final product’s intended use. The selection process should also involve evaluating the emulsifier’s compatibility with other formulation components, as well as its potential impact on the product’s sensory attributes, such as texture and feel. Proper knowledge of polysorbate emulsifiers enables formulators to create stable and effective products that meet consumer expectations while maintaining optimal performance.

When selecting polysorbate emulsifiers for your formulations, several key factors must be considered to ensure optimal performance and compatibility with your specific application. First and foremost, the HLB (Hydrophilic-Lipophilic Balance) value of the polysorbate is crucial. This value determines the emulsifier's ability to stabilize oil-in-water or water-in-oil emulsions. By aligning the HLB of the emulsifier with the desired type of emulsion, you can improve stability and prevent separation, enhancing the longevity and effectiveness of your product.

Another important factor is the compatibility of the polysorbate with other ingredients in your formulation. Understanding the chemical nature of your oils and active ingredients is essential, as some polysorbates may interact negatively with specific components, leading to undesirable changes in texture, appearance, or efficacy. Additionally, consider the viscosity andtexture of the final product. The choice of emulsifier should facilitate the desired mouthfeel or skin feel without compromising the product's overall stability or performance. By carefully evaluating these factors, you can make informed decisions that will enhance the quality and effectiveness of your formulations.

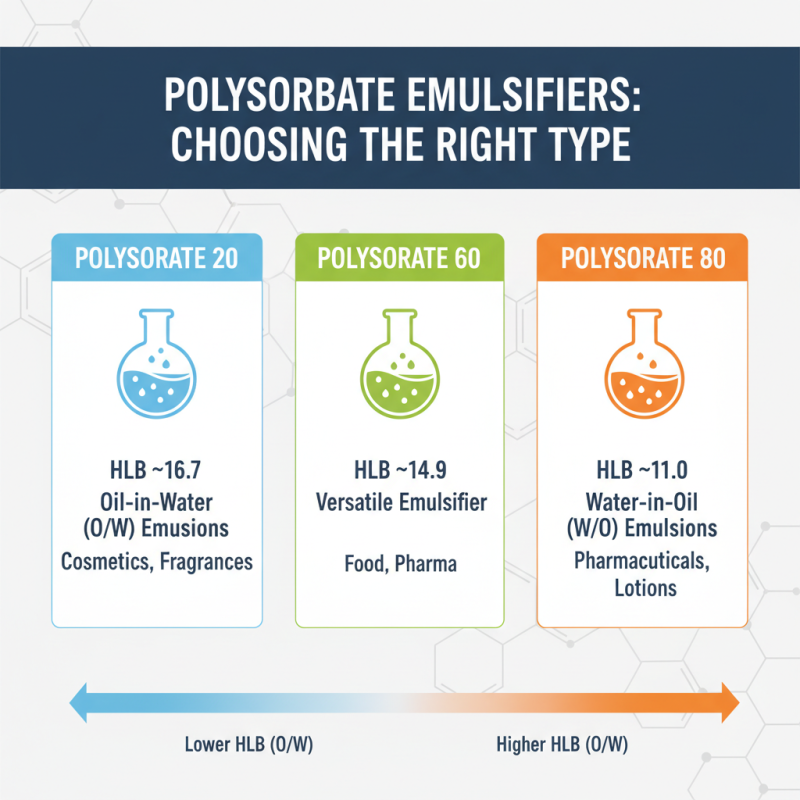

When it comes to formulating products that require emulsification, choosing the right polysorbate emulsifier is pivotal. Polysorbate emulsifiers, known for their versatility and efficacy, come in various types that cater to different applications. Among the most commonly used types are Polysorbate 20, Polysorbate 60, and Polysorbate 80, each differing in their hydrophilic-lipophilic balance (HLB) values. This balance significantly influences the emulsifier's effectiveness, with lower HLB values (like Polysorbate 20) being more suitable for oil-in-water emulsions, while higher HLB values (such as Polysorbate 80) excel in water-in-oil formulations.

Industry data suggests that the global market for polysorbate emulsifiers is projected to grow at a CAGR of 4.3% from 2021 to 2026, highlighting the increasing demand for effective emulsification in personal care, food, and pharmaceutical products. When selecting an emulsifier, it is essential to consider not only compatibility with other formulation components but also the intended application and regulatory requirements.

Tips: Always conduct compatibility tests to ensure that the chosen emulsifier works well with your other ingredients. Additionally, monitor the stability of the emulsion over time, as factors like temperature and storage conditions can significantly impact its performance. Lastly, stay informed about emerging trends and regulatory changes in emulsifier usage to maintain compliance and product efficacy.

When selecting the right polysorbate emulsifiers for your formulations, it’s essential to consider application-specific guidelines. Different formulations—ranging from food products to cosmetics—demand varying properties in emulsifiers such as hydrophilic-lipophilic balance (HLB) values. For instance, in food formulations, polysorbate 20 is commonly used for its ability to stabilize oil-in-water emulsions, making it ideal for salad dressings and sauces. In a contrasting application, cosmetic formulations may benefit from polysorbate 80, which offers excellent emulsification for creams and lotions due to its higher HLB, aiding in the formation of stable oil-in-water emulsions.

Furthermore, evaluating the expected thermal and pH stability of your formulation is crucial. Some polysorbates exhibit different characteristics under varying temperature conditions or pH levels. For example, if your product will undergo heat treatment, polysorbate 60, with its favorable thermal stability, may be the better choice. Additionally, understanding the interaction with other ingredients in the formulation can significantly affect the performance of the emulsifier. Assessing these factors—such as compatibility with active ingredients and preservation systems—ensures that your emulsifier not only meets the functional requirements but also contributes to the overall stability and quality of the final product.

When formulating products that require emulsification, choosing the right polysorbate emulsifier is crucial for achieving the desired texture, stability, and performance of your formulations. Testing and evaluating emulsifier performance involves several steps to ensure that your choice meets the specific needs of the product. Begin by examining the physical properties of your emulsifier, such as its HLB (Hydrophilic-Lipophilic Balance) value, which directly influences emulsification capabilities and stability.

Additionally, consider conducting stability tests under various conditions, such as temperature cycling and storage time, to observe how the emulsifier performs over time. An essential aspect of evaluating emulsifier performance is to analyze the final product’s viscosity, shelf life, and appearance. Conducting sensory evaluations may also provide insight into how the emulsification affects the product's usability and consumer acceptance.

**Tips:** Always maintain proper documentation during testing to track changes and improve future formulations. It is also beneficial to run small-scale trials before full production to minimize waste and fine-tune your emulsifier choice. Engage in comparative analysis by using multiple emulsifiers in similar formulations to determine which one yields the best results in terms of stability and consumer appeal.

| Emulsifier Type | HLB Value | Usage Level (%) | Stability at High Temperature | Compatibility with Oils | Viscosity Impact | Performance Rating |

|---|---|---|---|---|---|---|

| Polysorbate 20 | 16.7 | 1-5% | Good | Mineral Oils | Low Impact | 4/5 |

| Polysorbate 80 | 15.0 | 0.5-3% | Excellent | Vegetable Oils | Moderate Impact | 5/5 |

| Polysorbate 60 | 14.9 | 0.5-2% | Good | Animal Fats | Low Impact | 3/5 |

| Polysorbate 100 | 17.8 | 1-4% | Excellent | Synthetic Oils | High Impact | 5/5 |