Leave Your Message

The effective use of Latex Rubber Raw Material is essential in various manufacturing sectors. According to market research from Smithers, the global latex rubber market is projected to grow by 4.5% annually. This growth emphasizes the need for manufacturers to optimize their use of latex materials in production. They must adapt to changing consumer demands and sustainability initiatives.

Manufacturers face several challenges when utilizing Latex Rubber Raw Material. Some struggle with inconsistent quality and supply issues. In fact, a study by Technavio indicates that 25% of manufacturers cite quality control as a major hurdle. This reflects a need for better sourcing and processing methods to ensure a uniform product. Investing in advanced techniques can enhance the properties of latex rubber, improving durability and performance.

As the industry evolves, it becomes increasingly important to reflect on best practices. There is room for improvement in optimizing workflows and minimizing waste during the manufacturing process. By focusing on these areas, companies can maximize the benefits of Latex Rubber Raw Material while addressing their shortcomings. This strategic approach can lead to a more sustainable and profitable production cycle.

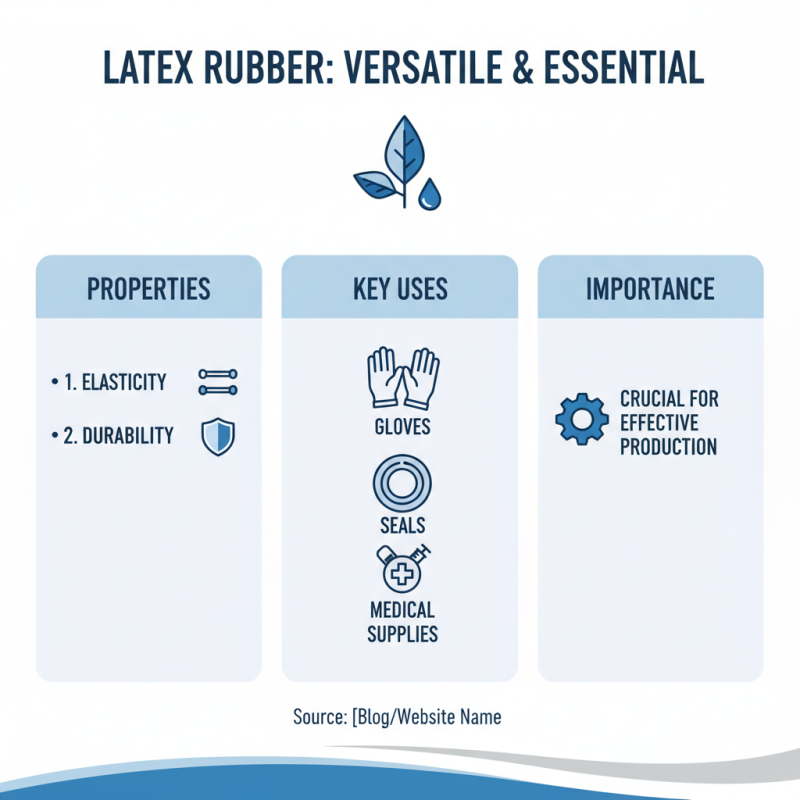

Latex rubber is a versatile material used in various manufacturing processes. Its elasticity and durability make it ideal for products like gloves, seals, and medical supplies. Understanding the properties of latex rubber is crucial for effective usage in production.

The raw material is derived from the sap of rubber trees. It contains natural proteins that can cause allergic reactions in some individuals. Therefore, manufacturers must account for these sensitivities when designing products. Additionally, latex rubber experiences degradation when exposed to UV light and certain chemicals. This can impact the longevity of the final product.

However, using latex rubber comes with challenges. Achieving the right balance of softness and strength requires careful formulation. Overlooking this could lead to premature wear or product failure. Manufacturers should routinely review their mixing processes to ensure quality and consistency. Testing prototypes in various environments helps identify any weaknesses. By focusing on these key aspects, the effective use of latex rubber in manufacturing can be enhanced.

Latex rubber is a versatile material used in various manufacturing processes. Key applications include the production of gloves, shoes, and seals. In 2022, the global latex market was valued at approximately $16 billion. According to industry reports, the use of eco-friendly processing methods has become essential. Manufacturers must focus on sustainability to meet rising consumer demands.

In glove production, manufacturers use dipping processes to create thin, durable layers. The latex is heated, allowing it to coat molds evenly. A common challenge is achieving consistent thickness. Inconsistent thickness can lead to product defects, impacting quality. It’s vital to monitor temperature and dipping time closely.

**Tip:** Regularly calibrate your equipment to ensure consistent results.

Another important process is foam manufacturing. Latex foam is often used in cushions and mattresses. It features excellent elasticity and breathability. A drawback is its potential for off-gassing, which can affect indoor air quality. Addressing this requires careful selection of chemicals and additives.

**Tip:** Use natural additives to reduce emissions.

Finally, in products like seals, latex is compounded with fillers for enhanced durability. This process can be complex. Manufacturers must strike a balance between cost and performance. Excessively cheap materials can compromise product integrity, leading to increased returns. Consider your material sources carefully.

| Manufacturing Process | Description | Applications | Advantages |

|---|---|---|---|

| Latex Dipping | A process where items are coated in liquid latex, allowing thick and uniform coverage. | Gloves, balloons, and other flexible products. | Excellent elasticity and strength. |

| Latex Molding | Creating objects by pouring latex into molds, allowing intricate shapes. | Toys, medical devices, and decorative items. | High detail accuracy and customizability. |

| Latex Blending | Combining latex with other materials to enhance properties. | Footwear, seals, and gaskets. | Improved durability and functionality. |

| Latex Casting | Pouring latex into a cast to form specific shapes. | Artistic sculptures and complex designs. | Versatility in design and easy production. |

Handling latex rubber requires precision and care. Latex can cause allergic reactions in some individuals. According to a study by the American Latex Allergy Association, about 1% to 6% of the general population may be affected. Therefore, it's crucial to prioritize safety in the manufacturing process.

Workers should wear gloves and masks when handling latex. Proper ventilation is essential to avoid inhalation of airborne particles. Training sessions on the specific risks associated with latex exposure can enhance workplace safety. Safety data sheets (SDS) must be easily accessible and understood by all team members.

In production settings, storing latex correctly is vital. Keep it in a cool, dry place, away from direct sunlight. Improper storage can lead to degradation. Moreover, regular inspections of storage areas can help identify potential hazards before they escalate. Safety should always come first, especially when dealing with materials that can pose health risks.

Quality control in latex rubber manufacturing is crucial. It ensures that products meet specific standards. Raw material sourcing plays a significant role. Using high-quality latex is essential. Suppliers should provide certifications. Inspect raw materials upon arrival to avoid issues later. A visual check can reveal inconsistencies in color and texture.

Processing methods also impact quality. Accurate mixing and temperature control are vital. Any deviations can lead to defects. Staff training is necessary. Workers should understand how to handle materials properly. Regular equipment maintenance can prevent malfunctions. Unscheduled downtime affects production schedules.

Testing finished products is important too. Conducting durability tests helps identify weaknesses. Sometimes, results may not meet expectations. This feedback is valuable for improvement. Document all quality checks to track progress. It builds a reliable record. Quality control is an ongoing process. Reflections on past errors can lead to better outcomes.

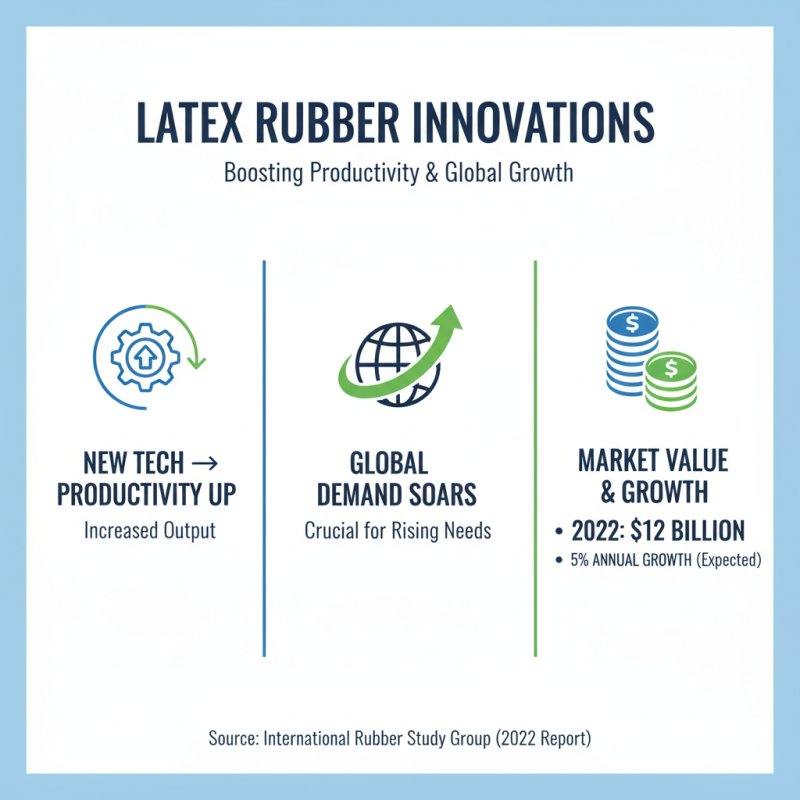

Innovations in latex rubber manufacturing technology are transforming the industry. Recently, a report by the International Rubber Study Group highlighted an increase in productivity. This growth is crucial as global demand for latex products rises. In 2022, the market reached a valuation of $12 billion, with expectations to grow by 5% annually.

New techniques, like aerogel mixing, are making latex products lighter and stronger. This innovation reduces materials without sacrificing durability. Companies are also exploring bio-based additives, improving sustainability. However, this shift isn't without challenges. Not all manufacturers have the resources to adopt these technologies. A 2023 survey found that only 45% of manufacturers use advanced technologies in their processes.

Quality control remains an issue with these innovations. Inconsistent product performance affects customer satisfaction. Manufacturers must ensure their processes are scalable and efficient. The industry must embrace continuous improvement. Feedback loops and research can guide better practices. In an evolving market, adapting to these innovations is crucial for staying competitive.