Leave Your Message

Choosing the right primary emulsifier for your formulations is a critical step in ensuring product stability and performance. As industry expert Dr. Emily Carter, a leading authority in cosmetic formulation science, states, “The selection of a primary emulsifier can make or break the stability of your product.” This highlights the importance of understanding not only the characteristics of emulsifiers but also how they interact with other ingredients within a formulation.

Emulsifiers play a pivotal role in creating stable mixtures of water and oil, which is crucial in a wide range of applications, from skincare products to food items. With numerous options available in the market, selecting the most suitable primary emulsifier can be overwhelming. Factors such as compatibility with other ingredients, the desired texture, and the stability of the final product must all be carefully considered. In this article, we will explore the top ten tips for choosing the best primary emulsifier, empowering formulators to enhance their products' efficacy and appeal while ensuring long-lasting stability.

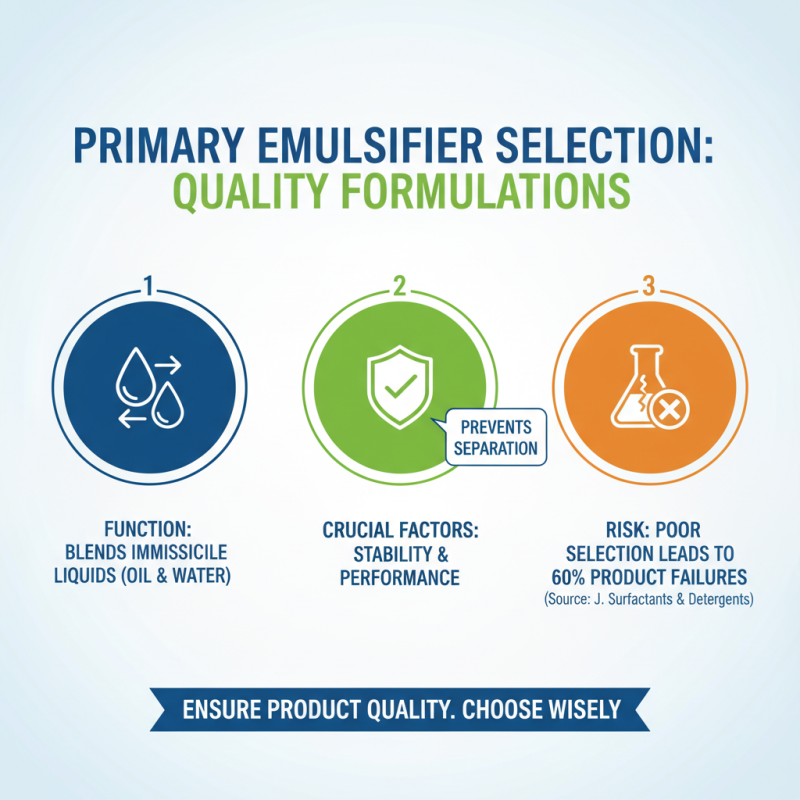

Emulsifiers play a crucial role in formulating stable and homogeneous products across various industries, particularly in food, cosmetics, and pharmaceuticals. These compounds facilitate the mixing of immiscible liquids, such as oil and water, by reducing surface tension and allowing for a smoother blend. According to a report by Grand View Research, the emulsifier market is projected to reach USD 9.4 billion by 2025, highlighting the growing importance of these ingredients in product formulation.

When selecting an emulsifier, it’s essential to consider the specific application and the desired stability of the formulation. For instance, non-ionic emulsifiers are often favored in cosmetic formulations due to their mildness and ability to work well at a wide range of pH levels. It's important to test various emulsifiers under different conditions, including temperature changes and shearing forces, to ensure optimal performance and consistency.

Tip 1: Evaluate the HLB (Hydrophilic-Lipophilic Balance) value of potential emulsifiers, as this determines their ability to stabilize oil-in-water or water-in-oil emulsions effectively.

Tip 2: Consider the source of the emulsifier; natural emulsifiers are increasingly preferred for their safety and sustainability, which align with consumer trends towards clean labeling.

By understanding the pivotal role emulsifiers play in formulations, industry professionals can make informed choices that enhance product quality and meet consumer expectations.

When selecting the ideal primary emulsifier for formulations, there are several critical criteria to consider. First and foremost, the emulsifier's HLB (Hydrophilic-Lipophilic Balance) value is pivotal. HLB values range from 0 to 20, with low values favoring oil-in-water (O/W) emulsions and high values favoring water-in-oil (W/O) emulsions. A comprehensive review from the Journal of Dispersion Science and Technology highlights that selecting an emulsifier with the appropriate HLB value is essential to ensure stability and performance in formulations, as miscalculating this can lead to phase separation and reduced shelf life.

Another significant factor is the emulsifier’s compatibility with other formulation ingredients, including active compounds, preservatives, and stabilizers. According to a study published in the International Journal of Cosmetic Science, incompatibility can compromise the effectiveness of both the emulsifier and the active ingredients, ultimately affecting product integrity and consumer satisfaction. It is also crucial to evaluate the emulsifier's sensory attributes, such as texture and feel on skin, as consumer preferences significantly influence market success. Recent market research indicates that over 60% of consumers deem the sensory profile of skincare products as critical for purchase decisions, underscoring the necessity for emulsifiers that enhance the overall user experience while maintaining formulation efficacy.

When selecting a primary emulsifier for your formulations, evaluating its compatibility with other ingredients is crucial to ensuring product stability and performance. An emulsifier functions by reducing the surface tension between the immiscible phases, such as oil and water. However, not all emulsifiers can work harmoniously with every ingredient in your formulation. Therefore, it's vital to assess potential interactions that could lead to the destabilization of your emulsion or the degradation of key ingredients.

One of the key aspects to consider is the charge of the emulsifier in relation to other components. For instance, cationic, anionic, and nonionic emulsifiers may interact differently with other charged ingredients. Additionally, the physical and chemical properties of the emulsifier, such as its hydrophilic-lipophilic balance (HLB), can greatly impact its effectiveness when mixed with other materials. Conducting compatibility tests through small-scale formulations can help identify issues, such as phase separation or precipitation, allowing formulators to refine their choices and ensure that all components work synergistically in the final product.

When selecting the best primary emulsifier for your formulations, assessing stability and performance characteristics is crucial to ensuring product quality. Emulsifiers serve as fundamental agents that facilitate the blending of immiscible liquids, such as oil and water. According to a report by the Journal of Surfactants and Detergents, nearly 60% of product failures in emulsified formulations can be traced back to inadequate emulsifier selection, highlighting the importance of thorough evaluation.

One key factor in assessing stability is the emulsifier's HLB (Hydrophilic-Lipophilic Balance) value. Optimal HLB values are essential for achieving desired emulsification properties; for example, a value between 8 and 18 is typically required for oil-in-water emulsions. Moreover, the performance characteristics should also consider the emulsifier's ability to withstand varying temperatures and pH levels. A study published by the International Journal of Cosmetic Science found that formulations utilizing stable emulsifiers demonstrated significantly enhanced shelf life, with a 30% reduction in phase separation over a six-month period compared to those using less stable alternatives.

Additionally, factors such as viscosity and sensory attributes must be considered, as they directly influence consumer acceptance. Data from industry analyses indicate that consumers prefer emulsions with a smooth texture and consistent feel, affecting their purchasing decisions. As such, the right emulsifier not only enhances stability and performance but also contributes to the overall marketability of the product.

When it comes to formulating stable emulsions, testing and optimizing emulsifier efficacy is crucial for achieving the desired product quality. Emulsifiers play a vital role in reducing interfacial tension between immiscible liquids, thus promoting stability and preventing phase separation. To assess their performance, formulators should begin with preliminary tests that measure viscosity, droplet size distribution, and stability over time under various conditions like temperature and pH fluctuations. These tests help identify which emulsifier offers the best initial performance metrics, setting the stage for further optimization.

Once the preliminary assessments are complete, the next step is to refine the formulation by adjusting emulsifier concentrations and exploring synergistic effects with other ingredients. It’s important to examine how different emulsifiers interact with one another and with various phase components. Formulators should conduct stability studies, including thermal cycling tests and accelerated aging tests, to simulate real-world conditions. By meticulously evaluating the results and gathering data, formulators can optimize the emulsifier selection and concentration for enhanced product performance, ensuring that the final emulsion meets the desired texture, stability, and shelf-life standards.