Leave Your Message

In the world of lubrication, grease plays a crucial role. The quality of grease directly depends on the choice of Grease Making Raw Materials. Selecting the right raw materials is not always straightforward. It requires careful consideration of various factors.

Different applications demand specific properties from grease. For example, high-temperature environments need special additives. Some materials may perform well initially but degrade over time. This inconsistency can lead to failures. Companies must understand the implications of their raw material choices.

Recent advancements have introduced new options in the market. However, some manufacturers still rely on traditional materials. This reliance can limit performance and innovation. Companies need to assess their strategies for optimal results. Identifying the best Grease Making Raw Materials will help in achieving superior performance.

Grease plays a crucial role in various industrial applications. It is essential for reducing friction, wear, and maintaining equipment health. A recent report by the Global Lubricants Market revealed that the grease segment accounts for approximately 15% of the overall lubricants market. This highlights its importance across multiple sectors, including manufacturing, automotive, and construction.

The composition of grease affects its performance. Key raw materials include base oils and thickening agents. According to industry studies, high-quality base oils improve lubrication effectiveness and enhance thermal stability. Moreover, the choice of thickener influences the grease’s consistency and load-bearing capacity. Lithium, calcium, and polyurea are popular thickeners recognized for their unique properties. However, the selection process can be complex and requires careful consideration. Inadequate formulation can lead to poor performance and equipment failure.

Sustainability is another growing concern. The demand for environmentally friendly lubricants is rising. The industry is slowly shifting toward bio-based and biodegradable options. However, these alternatives often trail in performance compared to conventional greases. This gap raises the question of whether we can truly meet both performance and sustainability goals simultaneously. Balancing effectiveness and environmental responsibility remains a challenge that the industry must address.

When discussing

raw materials

in grease production, it's crucial to understand their impact on performance.

Base oils are among the primary components. They comprise

70-90% of the grease formulation. These oils can be mineral, synthetic, or biobased. According to industry reports, synthetic oils offer superior thermal stability and lubrication properties. However, they tend to be more expensive.

Thickeners also play a significant role. Common thickeners include

lithium soaps and polyurea. These substances determine the consistency and temperature resistance of the grease. For example, lithium-based thickeners are popular due to their reliability. Yet, the rising costs and environmental concerns over mineral oils mean that manufacturers are exploring alternatives.

Additives are the final piece of the puzzle. They enhance the performance of the grease. Antioxidants, anti-wear agents, and corrosion inhibitors are common examples. Reports indicate that the right additives can increase grease lifespan by up to

25%. Nonetheless, balancing cost and performance remains a challenge. Increasingly, manufacturers must evaluate the trade-offs between raw material quality and overall cost-effectiveness.

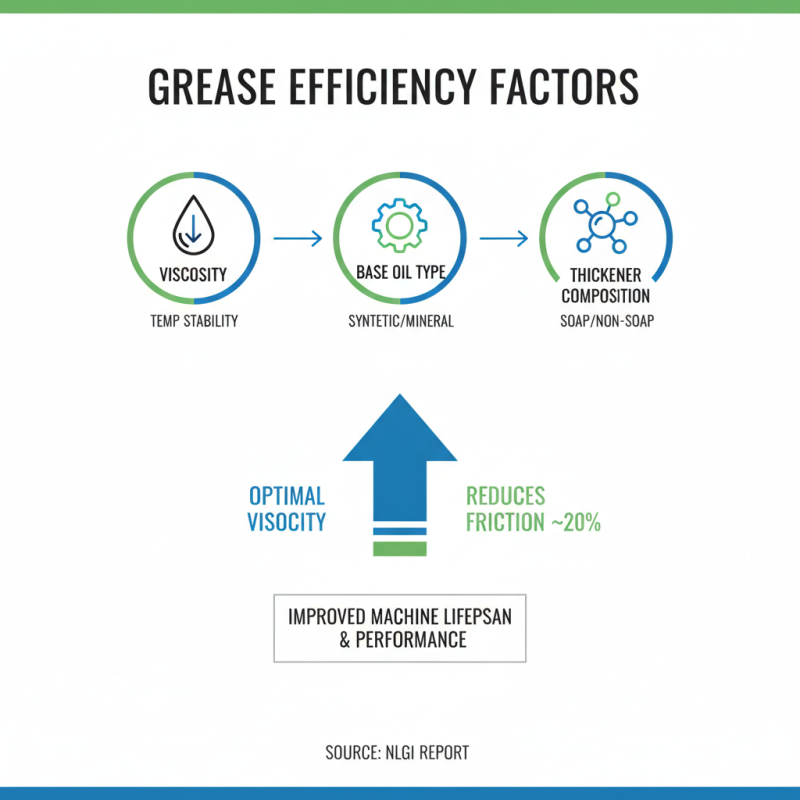

The efficiency of grease heavily relies on specific performance factors. These factors include viscosity, base oil type, and thickener composition. Viscosity plays a crucial role in ensuring that grease retains its lubricating properties under varying temperatures. A report from the National Lubricating Grease Institute highlights that optimal viscosity can reduce friction by about 20%. This improvement is significant for enhancing machine lifespan and performance.

Base oil type also influences grease efficiency significantly. Synthetic base oils can provide better thermal stability and lower volatility compared to mineral oils. Data shows that using synthetic oils can improve lubrication performance by 40% in high-temperature applications. Meanwhile, thickeners contribute to the grease's resistance to water and breakdown under stress. According to recent studies, POLYUREA thickeners outperform lithium-based options in specific scenarios, offering improved lasting stability. Their unique properties can enhance performance but may also present challenges in formulation flexibility.

While these factors are vital, balancing them is not straightforward. Selecting the right combination requires careful consideration of operational conditions and desired outcomes. Manufacturers often struggle with this balance, leading to suboptimal formulations that do not meet performance expectations. Addressing these issues may involve additional research and development. Innovating in raw material selection will be key to maximizing grease efficiency in the future.

In the grease manufacturing industry, environmental concerns are increasingly vital. The extraction and processing of raw materials often harm ecosystems.

Pollution from manufacturing processes contributes to air and water quality degradation. Many companies focus solely on profitability, overlooking these consequences.

This negligence demands reflection and reform in sourcing practices.

Sustainable raw material choices are crucial. Biodegradable ingredients can reduce environmental impact.

However, these alternatives may not always provide optimal performance. Conflicting goals arise, where enhancing the product seems to clash with eco-friendly intentions.

Moreover, the supply chain must be transparent. Hidden practices can undermine sustainability efforts.

Emphasizing innovation, the industry should explore alternative sources of materials. Research into plant-based oils and recycled content could pave the way.

Each step taken towards sustainability carries challenges. Balancing performance and environmental integrity requires dedication and creativity.

The path forward is complex, but reflection on current practices is essential.

The grease industry is evolving rapidly. Growing demands for performance and sustainability drive this transformation. Raw materials for grease formulation are central to these changes. New organic and synthetic options are emerging. They offer enhanced lubrication, better thermal stability, and reduced environmental impact.

One key trend is the increased use of bio-based materials. These alternatives show promise for lowering carbon footprints. While their performance can be impressive, consistency remains a concern. Formulators need to experiment, striking the right balance between sustainability and efficiency. This often leads to unexpected challenges and requires creative solutions.

Also noteworthy is the shift toward multifunctional additives. These materials can enhance the properties of conventional greases. However, finding the right combination can be tricky. Detailed understanding of each component is vital. Some options might interact negatively, leading to subpar performance. History teaches us the importance of rigorous testing and validation. The path to optimal grease performance is not without obstacles.