Leave Your Message

In the rapidly evolving world of industrial applications, the importance of Primary Emulsifiers cannot be overstated. According to market research by Smith & Associates, the primary emulsifier market is projected to grow by 5% annually through 2026. This growth is attributed to the increasing demand for stable emulsions in various sectors, such as food, cosmetics, and pharmaceuticals. As industries focus on product efficacy, the role of effective emulsifiers becomes critical.

Dr. Emily Chen, a leading expert in emulsification technology, once said, “Understanding the right type of Primary Emulsifier is essential for enhancing product performance.” Her insights reflect a growing recognition in the industry. Various emulsifiers, like lecithin and mono- and diglycerides, showcase unique functionalities. These emulsifiers can improve texture, extend shelf life, and enhance visual appeal, yet their selection and application can still be confusing for many manufacturers.

The challenge lies in matching the right emulsifier to specific product needs. Many industry players are still navigating this complexity. With new formulations emerging, the industry must keep pace. The next few years will define how effectively industries harness primary emulsifiers to drive innovation and meet consumer demands.

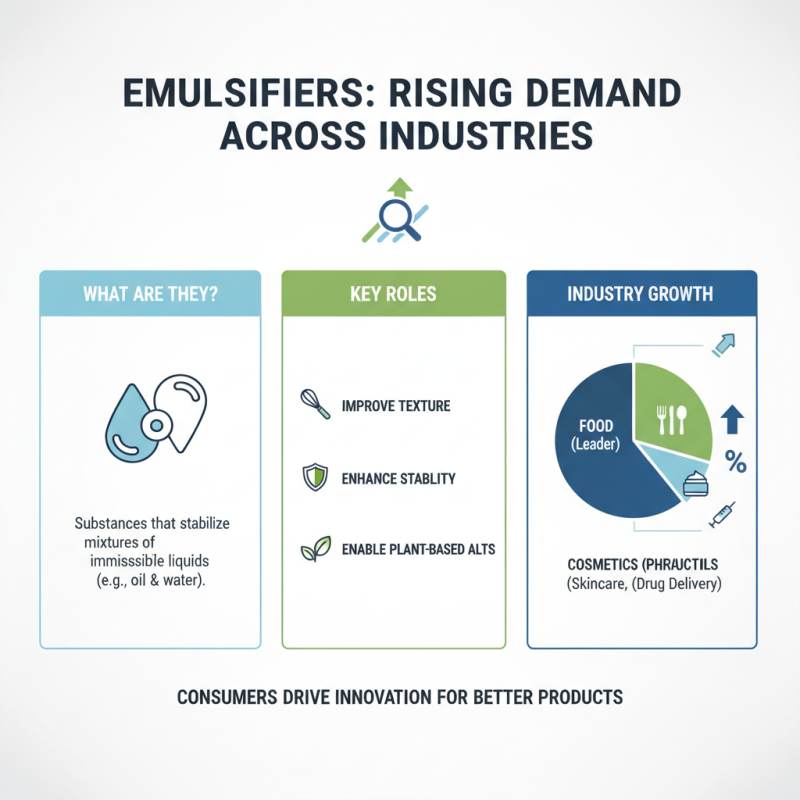

In industrial applications, primary emulsifiers function as vital agents. These substances help mix two immiscible liquids, such as oil and water. Various types exist, including ionic and non-ionic emulsifiers. Each type has a unique role in different sectors like food, cosmetics, and pharmaceuticals.

Food industries often rely on emulsifiers for stabilizing mayonnaise and sauces. In cosmetics, they aid in creating lotions and creams that feel smooth. Pharmaceutical applications utilize emulsifiers in formulating effective topical treatments. However, the choice of emulsifier can be tricky. Not all emulsifiers work well in all conditions. Testing is essential to find the right match.

Tip: Always check for compatibility. Emulsifiers should align with the product's intended use.

In some cases, manufacturers face challenges. Some emulsifiers may not provide the desired stability over time. Issues like separation can arise after storage. This requires ongoing evaluation of emulsifier performance. Certain emulsifiers can also affect taste or skin feel. Therefore, user feedback is invaluable.

Tip: Consider user experience and stability tests vital for development.

When discussing emulsifiers, their key characteristics are crucial. Emulsifiers stabilize mixtures of oil and water by reducing surface tension. This enables the formation of stable emulsions, essential in various industries. For instance, the food industry relies on emulsifiers to create smooth dressings and sauces. A report highlights that around 70% of the emulsifiers used in food are synthetic.

Some top emulsifiers include lecithin, mono- and diglycerides, and polysorbates. Lecithin, derived from soybeans or egg yolks, has a natural origin. It provides excellent emulsifying properties and is safe for consumption. Mono- and diglycerides are often used in baked goods, helping maintain texture. Polysorbates, while effective, have faced scrutiny for their long-term health effects.

In personal care, emulsifiers contribute to product stability and texture. Many creams and lotions rely on emulsifiers for a desirable feel on the skin. Interestingly, the concentration of emulsifier influences product performance. A study found that increasing concentration leads to better stability but could also cause greasiness. This presents a balance between aesthetics and functionality that requires further exploration.

Emulsifiers play a crucial role in various industries, especially in food, cosmetics, and pharmaceuticals. The demand for these substances is rising. Consumers seek better textures and improved stability in products. This trend is evident in plant-based alternatives, where emulsifiers help achieve desirable consistency. The food industry leads, but other sectors follow closely.

In cosmetics, emulsifiers are vital for creams and lotions. They create a smooth product that consumers love. The challenge lies in sourcing eco-friendly options. Many companies face scrutiny over sustainability. The shift toward cleaner labels is evident. However, finding the right balance between effectiveness and safety remains a concern. Meanwhile, the pharmaceutical industry relies on emulsifiers for drug delivery systems. These systems require precision. Yet, the need for innovative solutions is pressing.

Market trends show a growing focus on natural emulsifiers. Many companies are struggling to meet both performance and environmental standards. This situation creates an opportunity for innovation. Not every product on the shelf meets consumers’ expectations, indicating room for improvement. The ongoing evolution in emulsifier technology suggests a dynamic marketplace, ripe for exploration and integrity. As industries adapt, the future looks promising but requires careful navigation of emerging needs.

When exploring emulsifiers, the choice between natural and synthetic options is crucial. Natural emulsifiers are derived from renewable resources. They often have a lower environmental impact. Common examples include lecithin and beeswax. These can enhance texture in food products. Consumers often prefer these for their perceived safety. However, they can vary in consistency and potency.

Synthetic emulsifiers, on the other hand, are engineered for specific functions. They offer reliability in formulation and longer shelf life. Their uniformity provides manufacturers with control over texture and stability. Yet, some consumers express concerns about potential health effects. This raises questions about their long-term use.

Tip: Always check ingredient lists. Understanding emulsifiers can lead to better choices. Experiment with different emulsifiers in recipes to find what works best. Reflect on how these choices affect taste and texture. It's worth considering the trade-offs between natural and synthetic. Sometimes, the right choice isn't so clear.

| Emulsifier Type | Category | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Lecithin | Natural | Food products, cosmetics | Biodegradable, safe for food | Higher cost, limited stability |

| Polysorbate 80 | Synthetic | Bakery, dressings, pharmaceuticals | Excellent stability, versatile | Potential health concerns, chemical additives |

| Sodium Stearoyl Lactylate | Synthetic | Baked goods, dairy | Improves texture, enhances dough stability | May not be suitable for clean label products |

| Casein | Natural | Dairy products, sauces | Natural source, nutritional benefits | Allergen for some individuals |

| Glycerol Monostearate | Synthetic | Ice cream, margarine | Improves creaminess, stability under heat | Not suitable for vegan products |

In the food industry, emulsifiers are essential. A case study on salad dressings demonstrates their role in maintaining product stability. This application shows how emulsifiers help blend oil and vinegar. Without them, separation occurs, and the product becomes unappealing.

Cosmetic manufacturers frequently rely on emulsifiers for creams. A notable study revealed the impact of emulsifier selection on texture and absorption. Customers prefer smooth creams that don’t leave a greasy residue. Yet, some emulsifiers can be sticky. This creates challenges for formulators who seek the perfect balance.

In pharmaceuticals, emulsifiers aid in drug delivery. A recent project improved the solubility of certain medications. While it increased bioavailability, some formulations still encountered stability issues. Emulsifiers play a key role but are not flawless. The importance of testing and refining cannot be overstated.