Leave Your Message

Cleaning is essential in various industries, and the choice of cleaning agents is crucial. Nonionic surfactants have gained recognition for their effectiveness in cleaning applications. According to a recent industry report, the global surfactant market is expected to reach $45 billion by 2025. Nonionic surfactants, in particular, hold a significant share due to their versatility and performance in different cleaning scenarios.

Nonionic surfactants are known for their gentleness on surfaces. They effectively remove dirt and grease without harsh reactions. This attribute makes them suitable for delicate fabrics and sensitive surfaces. However, relying solely on nonionic surfactants may not always yield optimal results. Factors such as water hardness and temperature can affect their cleaning power. Adapting the usage according to specific cleaning needs is vital.

Despite their advantages, users often overlook certain imperfections in cleaning processes. There may be a tendency to underestimate the importance of dosage and mixing techniques. Recent studies indicate that improper usage can diminish cleaning efficiency significantly. Thus, understanding how to leverage nonionic surfactants effectively is critical for successful cleaning outcomes.

Nonionic surfactants are critical in many cleaning applications. They are unique because they do not carry a charge. This quality allows them to work well in both soft and hard water. According to industry research, nonionic surfactants represent approximately 35% of the surfactants market, highlighting their significance in cleaning formulations.

These surfactants effectively remove dirt and grease. They can emulsify oils and help stabilize mixtures. This characteristic makes them ideal for a range of cleaning products, including detergents and industrial cleaners. Various studies indicate that nonionic surfactants have a low environmental impact, making them a preferred choice for eco-conscious formulations.

Tips: When using nonionic surfactants, consider their concentration. Too much can lead to a sticky residue. Always test on a small area first. Also, temperature plays a role; warmer water enhances their performance. It’s important to lean towards balance; an oversaturated solution may not yield optimal results. Remember, while these surfactants are effective, they require careful handling and formulation.

Nonionic surfactants are crucial in various cleaning applications. They possess unique properties that make them effective. These surfactants do not carry a charge and thus work well in different pH levels. This versatility is essential for formulating products that can tackle both oily and aqueous dirt. According to industry reports, nonionic surfactants account for over 30% of the surfactant market, showcasing their importance in cleaning solutions.

There are several types of nonionic surfactants, each with distinct properties. Alkyl polyglucosides (APGs) are biodegradable and gentle on skin. They are derived from renewable resources. Their mildness makes them suitable for personal care products. Another category is amine oxides, which enhance cleaning efficiency. They create foam and improve soil removal. The combination of efficiency and eco-friendliness is appealing in today's market.

Despite the advantages, nonionic surfactants have limitations. Some may require higher concentrations to achieve the desired cleaning effect. This can lead to increased costs and potential environmental concerns. Additionally, formulators must consider compatibility with other surfactants. Striking the right balance is often challenging. The quest for the perfect nonionic surfactant continues, encouraging further research and innovation in this field.

This chart illustrates the effectiveness of various properties of nonionic surfactants in cleaning applications. Each property is measured on a scale from 0 to 100, demonstrating where nonionic surfactants excel and where improvements are needed.

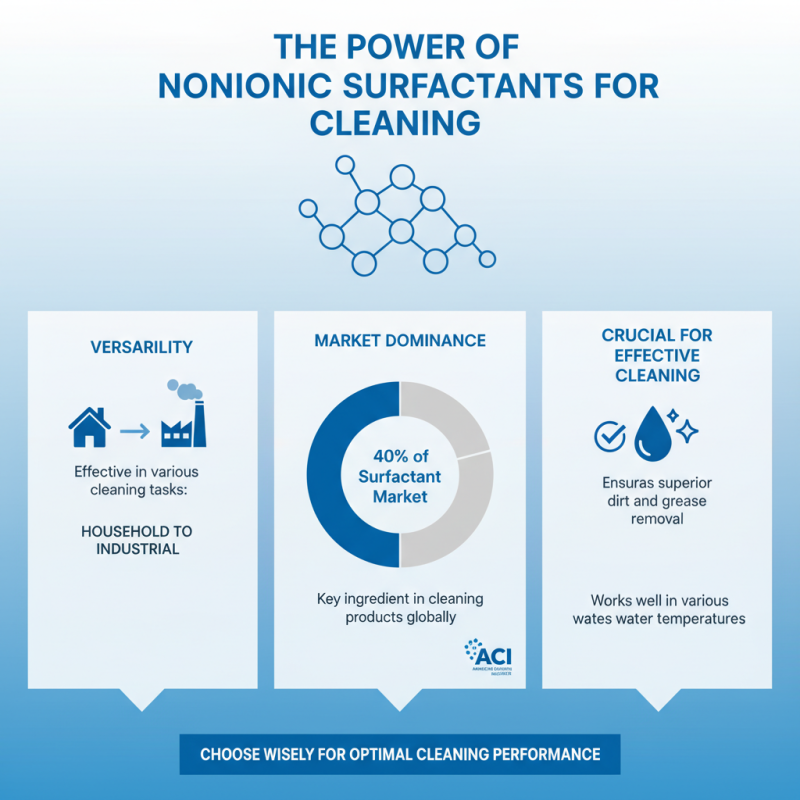

Choosing the right nonionic surfactant is crucial for effective cleaning. Nonionic surfactants are versatile. They work well in various cleaning tasks, from household use to industrial applications. According to a study by the American Cleaning Institute, nonionic surfactants make up about 40% of the surfactant market. This highlights their significant role in cleaning products.

When selecting a nonionic surfactant, consider the nature of the contaminants. For oily stain removal, nonionic surfactants with higher hydrophilic-lipophilic balance (HLB) values work best. Lower HLB values are suitable for removing dirt and dust. An important factor is the cleaning solution's pH level. Some nonionic surfactants can break down in extreme pH conditions, losing their effectiveness.

**Tip:** Always check compatibility with surfaces. Test on a small area first. If unsure, consult safety data sheets for guidance. Being informed prevents damage to surfaces and ensures better results.

Another detail to ponder is environmental impact. Many nonionic surfactants are biodegradable. However, their production processes may still pose challenges. So, it's wise to choose ones with eco-friendly certifications. Research indicates that the market trends favor sustainable options. This reflects a growing consumer demand for greener cleaning solutions.

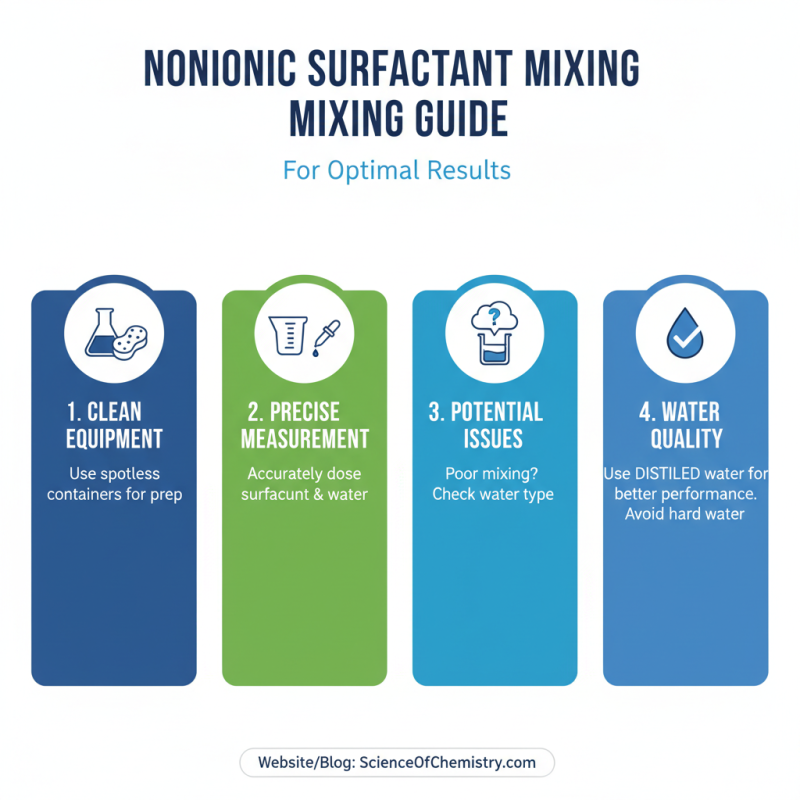

Mixing nonionic surfactants requires careful attention. Use clean containers for preparation. Always measure the surfactant and water accurately. Sometimes, the mixture may not form properly. This could be due to water quality. Hard water can reduce effectiveness. Try using distilled water when possible for better results.

When using nonionic surfactants, check the temperature. Some surfactants perform better in warm water. However, extreme heat can degrade their properties. Mixing should be done slowly. Rapid mixing can introduce air, creating foam. Foam is not always desirable and can complicate cleaning.

Experiment with different concentrations. Not all surfaces need the same dilution. An overly concentrated solution might leave residues. On the other hand, a too-dilute solution may not clean effectively. Always test on a small area first. This prevents potential damage to surfaces. Tracking your results will help refine your methods.

Working with nonionic surfactants requires attention to safety. These compounds are often gentle but can pose risks. Always use them in well-ventilated spaces. Avoid skin contact as some can irritate. Wear gloves and goggles for extra protection.

When mixing surfactants, read all safety data sheets. This ensures proper handling and reduces risks. Understand the concentration levels you are working with. High concentrations can increase the likelihood of irritation. Make sure to store them securely, away from children and pets.

Tips: Keep a first aid kit nearby. This is a smart move if accidents occur. Be aware of what to do in case of spills. Clean up any leaks quickly to minimize exposure. Always test a small area for reaction before widespread use.

| Cleaning Application | Recommended Nonionic Surfactant | Dilution Ratio | Safety Precautions |

|---|---|---|---|

| Household Surface Cleaning | C12-15 Alcohol Ethoxylate | 1:10 | Use gloves and goggles; ensure proper ventilation. |

| Carpet Cleaning | C9-11 Alcohol Ethoxylate | 1:15 | Test on a small area first; avoid contact with skin. |

| High-Pressure Cleaning | Nonylphenol Ethoxylate | 1:20 | Wear protective clothing; avoid breathing in vapors. |

| Industrial Equipment Cleaning | Fatty Alcohol Ethoxylate | 1:30 | Use in a well-ventilated area; utilize appropriate PPE. |

| Auto Detailing | Sodium Laureth Sulfate | 1:5 | Avoid skin contact; wear gloves and masks. |